Prestressed ConcretePrestressed Concrete

Prestressed concrete is a type of concrete construction material that incorporates internal stresses introduced to counteract the anticipated stresses that occur when the structure is subjected to loads. This method allows for increased strength and durability compared to traditional reinforced concrete.

Here's how it works:

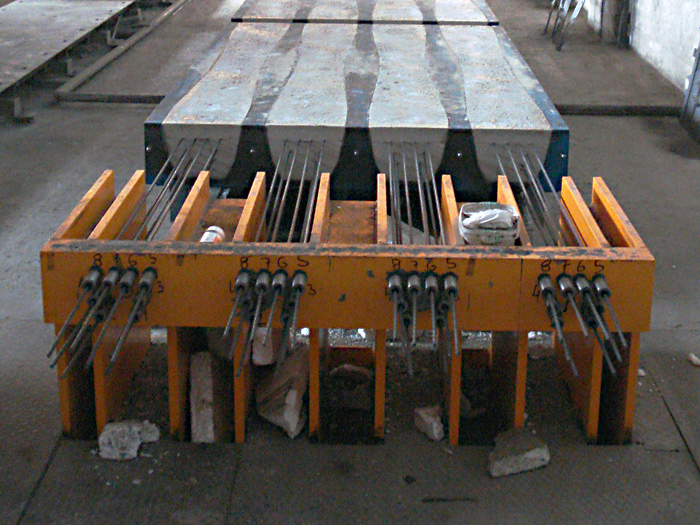

Pre-tensioning: In pre-tensioned concrete, high-strength steel tendons or cables are tensioned between anchorages before the concrete is poured. Once the concrete has hardened and gained sufficient strength, the tension on the tendons is released, transferring compression forces to the concrete. This process helps to counteract the tensile stresses that occur when the structure is loaded.

Post-tensioning: In post-tensioned concrete, ducts or sleeves are embedded within the concrete before it sets. High-strength steel tendons or cables are then inserted into these ducts and tensioned after the concrete has cured to a certain strength. The tendons are anchored at each end, and once tensioned, they impart compressive forces on the concrete, enhancing its strength and allowing for longer spans and reduced structural thickness.

Prestressed concrete offers several advantages:

Increased Strength: By introducing internal compression forces, prestressed concrete can withstand higher loads and stresses than traditional reinforced concrete, allowing for longer spans and thinner sections.

Durability: The precompression helps to minimize cracking and deformation under load, improving the durability and longevity of the structure.

Reduced Material Usage: Prestressed concrete structures can often be designed with reduced material usage compared to traditional reinforced concrete, leading to cost savings and environmental benefits.

Flexibility in Design: Prestressed concrete allows for more flexibility in architectural and structural design, enabling engineers to create innovative and efficient structures with longer spans, fewer supports, and distinctive shapes.

Prestressed concrete is commonly used in a variety of construction applications, including bridges, buildings, parking structures, stadiums, and offshore structures. It has become an essential material in modern construction due to its ability to achieve superior performance, efficiency, and aesthetic appeal.

Thank you,